Yisheng is the production of manganese steel, jaw plates, hafnium and other alloying elements, the content is selected according to the strength and abrasiveness of the crushed stone. The TC-liner is made of standard C and D alloys and reinforced with titanium carbide inserts. They exhibit higher resistance to shock loads and cracking forces. This effect is achieved through a special casting process and heat treatment of the finished product. During the test, the working time of the liner with liner was 1.5 to 4 times longer than that of the classic manganese steel without liner wear.

Applications: PEV jaw crusher is suitable for coarse, medium and tertiary crushing of various ores or rocks with compressive strength of no more than 300Mpa. It is suitable for mining, sand and gravel yards, cement plants, road construction, metallurgy, chemical and other industries

Operational advantages

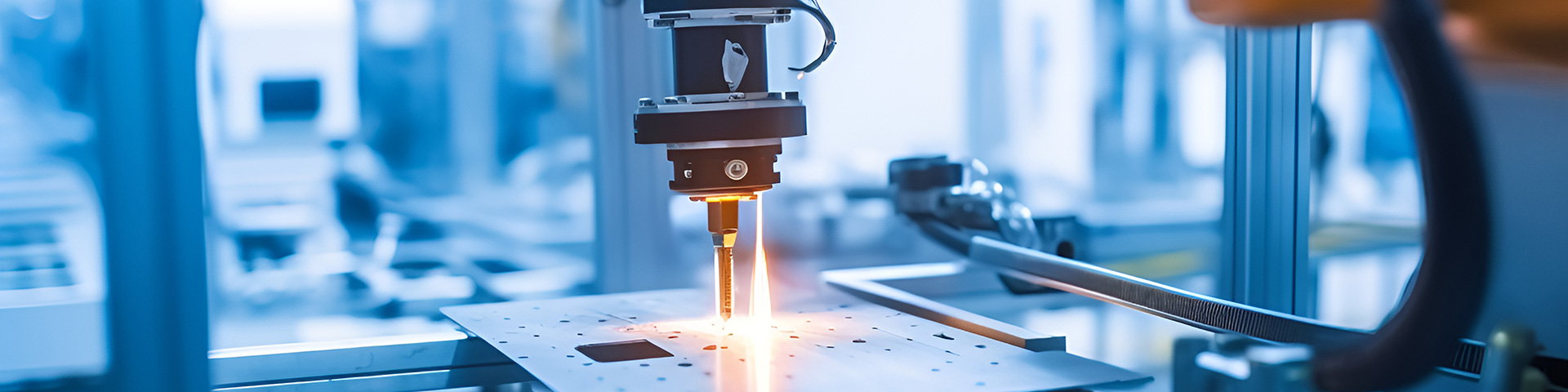

The motor drives the main engine pulley through the V-belt, and the main engine pulley drives the eccentric shaft, so that the moving jaw makes a reciprocating up and down periodic change movement according to the determined regular motion trajectory, so that the material in the crushing chamber is crushed, and the material is discharged by the discharge port by its own weight.

How it works

The replacement of worn parts for jaw crushers is a significant expense for any crushing and processing plant. The more frequently a factory needs to make repairs, the less efficient its production process becomes, ultimately leading to lower profits.

Yisheng's experts studied the operating conditions and found that the problem of short operating time was related to the large amount of ore in the feed. Based on the lining drawings and feed parameters used by the customer, our engineers developed a jaw plate that was more permeable to crushing and hard and abrasive. As a result, we have managed to increase not only the operating time, but also the quality of the finished product.

Project examples

Raw material condition: limestone

Equipment: ZSW2060/1 feeder, PEV1200X1600/1 jaw crusher, PF1520/1 impact crusher, 8XHL1280/1 high-efficiency sand making machine, several vibrating screens, and several sets of conveyors

Finished product requirements: 0-5mm, 5-10mm, 10-20mm, 20-31.5mm

Output requirements: 1200T/H

The crushing raw material of this site is limestone, which is not hard, so the selection of impact crusher can achieve a more ideal crushing effect and reduce the energy consumption and equipment purchase cost per unit capacity. Dahongli impact crusher enlarges the optimization of the crushing cavity type, high-strength and high-chromium/manganese steel casting lining, which can extend the replacement cycle of wearing parts to a greater extent, and the hydraulic cover opening device makes maintenance safer, more convenient and faster. With Dahongli high-efficiency sand making and shaping machine, one machine, shaping + sand making two effects, it reduces the investment amount for customers and reduces the construction area of the site. The narrow terrain has more area at the pass, which is convenient for the safe passage of vehicles.